BEHIND THE PRODUCT: TRAIL KNEE

We sat down with our product designer and developer, Travis Bilton, to see what went into our ever popular Trail Knee pad. Read on to see why our Trail Knee has become one of the best do it all MTB knee pads.

Let’s start at the beginning — when developing a knee pad from scratch, what are the first steps you take, and what does your development process look like from concept to prototype?

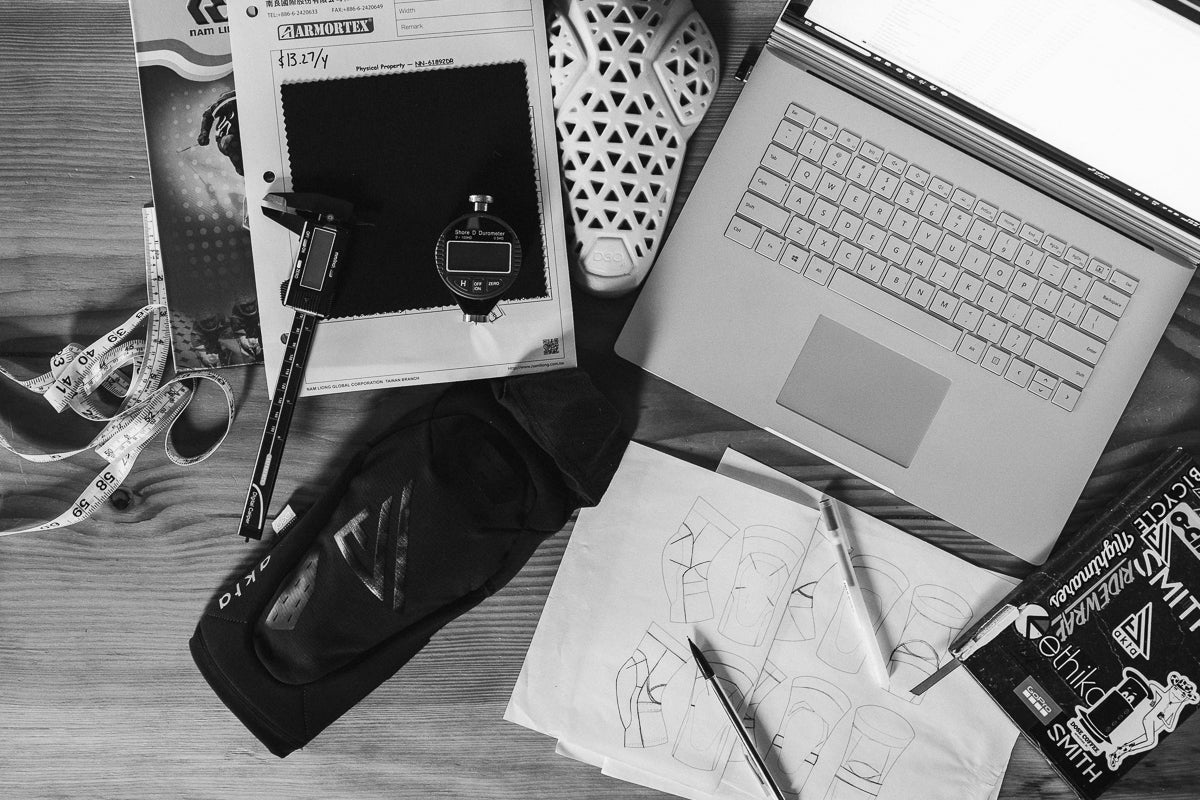

The first steps for this product were very different from how I typically start the design process. When the decision was finally made to go full-on and start akta, the Trail Knee Pad was the first product I started working on and the last one I approved to go into production. I knew exactly what I wanted in a knee pad, and this is what I’d been wanting to design for many years. When I was designing for Race Face and YT (RIP), I had three knee pads and two elbow pads get cancelled right before they were about to go into production. Between all those projects—the testing with athletes, testing different materials, learning what was working and what wasn’t—I was able to apply all that knowledge into this one knee pad. In many ways, those projects were my testing phase, and I was able to get to the prototyping phase much sooner. The product research, moodboards, sketches, and material choices all came together fairly quickly because of my past projects. Approval for production was a different story…

How many iterations or test versions did you go through before landing on the final production model? Any memorable challenges or surprises along the way?

I believe it was eight in total, if you count size sets and pre-production samples. Typically, you should be close to production level after three prototypes. I definitely tested my vendor’s patience, especially for a new brand they had never produced for before. Kind of funny—during our third production run of knee pads, my merchandiser at this vendor told me there was an error with one of my trims; it was off by 3mm. She said, “I was going to ask if you were okay with this, but I knew you wouldn’t be, so I went ahead and had it redone.” She also made sure I knew that the other brands they produce for—who are 10x bigger than us—would have approved the trim haha.

Getting the fit perfect was definitely the biggest challenge. One thing I tried on early protos was an open back-of-knee design. It seems to make sense on paper and helps increase breathability, but it sacrifices fit too much. Having a full-back design keeps a consistent compression fit around the knee. The open back caused materials to flare outward at the sides and allowed the pad to wander too much when pedalling, which caused chafing, and it wouldn’t stay securely in place during a crash.

I would usually deconstruct and rebuild protos to reduce materials in certain areas or change the placement of certain seams or elastics. It was a cool experience to see how the smallest changes can really impact the whole fit of the product. When akta finally went live, we hadn’t even received our knee pads yet. I think they were about three months behind schedule—and that was definitely on me for making some last-minute changes.

Having worked with other brands before founding akta MTB, were there limitations in design or manufacturing that you felt restricted by? What was the first thing you implemented once you had full creative control?

Designing for larger companies can usually turn into “design by committee,” with the loudest voice in the meeting dictating the direction of a product. That’s not always a bad thing, as many minds working together can create great things—especially when each member of the team knows when to stay in their lane. I wouldn’t necessarily say that was the case at the previous companies. I was often answering to a CFO who had zero textile experience or being told to make something cheaper. There were also times when design would be outsourced to a design agency with a fancy website. They would pitch these great ideas on paper and deliver a cool-looking 3D render, but it was completely impractical in real use. I think that comes down to designers not having experience using the final product in its intended environment.

Everything akta produces is designed and tested 100% by mountain bikers. The first steps for me at akta were pretty straightforward: design the pad—or any of our products—that I would want to wear any time I’m on an MTB ride. This is basically the knee pad I’ve wanted to make for almost 10 years.

Where does this knee pad sit in a rider’s protection setup? Was it built with a specific discipline in mind—trail, enduro, or more of an all-rounder?

I would simply call this an MTB knee pad. Whether you’re riding trail, enduro, or DH, this knee pad will perform at all of it. Nowadays, it's very common for people to have one bike for all of these different disciplines, as bikes are so capable now—I figured a knee pad should be the same way. Of course, there are more focused knee pads for all those genres, but I think this is the best option if you were to get a single knee pad for all your riding.

This has quickly become one of akta’s most popular products—what do you think makes it resonate so strongly with riders?

I think there are a few things that have made this a top product: comfort, staying in place for an entire ride, the overall quality, and its simplicity—all while still offering more protection than a standard sleeve design. I wanted to create a pad that I didn’t instantly want to take off my legs after a ride. I’ve found myself wearing these for hours after a ride without even thinking about it. But maybe the top reason is that they stay in place. It’s normal to be out for a 3–4 hour pedal and not have to touch or adjust the pad once, which is pretty rare with many other pads out there.

A pedal-friendly pad that doesn't sacrifice any level of protection. A blend of durable, highly breathable materials and features allow this to be the new standard in trail knee protection.